TM 10-5410-221-24

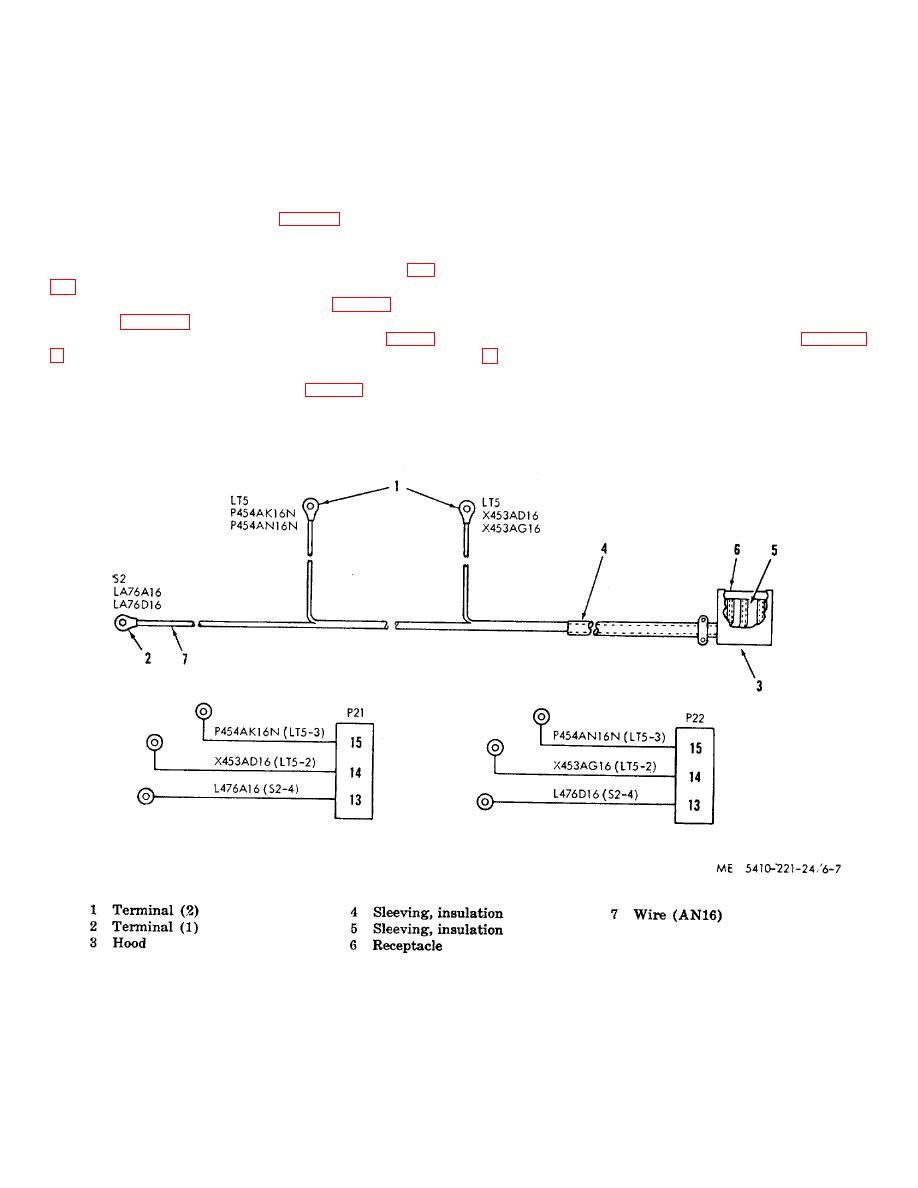

of a female connector and three electrical leads to

expose soldered wire connections to connector

provide interconnection between lights LT3, LT5 and LT7

receptacle (6). Unsolder connections and remove wires

and light switch S2.

(7) from receptacle (6). Remove sleeving (4, 5).

b. Removal.

d. Repair. Inspect wires and insulation sleeving

(1) Disconnect harness assemblies (11 12)

for abrasions and cuts. Minor cuts and abrasions are

from receptacle boxes J21 and J22 located on the

acceptable and may be repaired by wrapping with vinyl

shelter ceiling.

tape. Replace individual wires if cut or otherwise

(2) Remove screws (1, fig. 6-8) and remove

damaged.

Note. Cuts or abrasions of harness assemblies

cover plates (2). Remove nuts (3), washer (4) and screw

(5) and remove harness clamp (6). Remove screw (7)

may be due to sharp edges of electrical raceways,

and yoke (8) and remove harness assemblies (11, 12 fig.

interference with other components or improper

handling. The cause shall be determined and eliminated

(3) Disconnect terminals (1, 2, fig. 6-7) from

before installation of the harness assemblies.

e. Assembly.

LT5 light (para 2-30) and S2 switch

Assemble light wiring harness

(4) Pull the harness assemblies (11, 12 fig. 6-

assembly in reverse order of disassembly using figure 6-

c. Disassembly.

(1) Install insulation sleeving (4, 5) over wires

(1) Remove terminals (1, 2, fig. 6-7)

(7) and push back to expose connection end. Solder

(2) Remove hood (3) from harness.

wires (7) to receptacle (6) according to Specification MIL-

(3) Slide insulation sleeving (4, 5) back to

S-6872 using Sn60

Figure 6-7. Fluorescent lights junction box disassembly.

6-8