TM 10-5410-224-14

(4) Thoroughly clean surfaces to be caulked by

,

wiping with a cloth dampened in solvent.

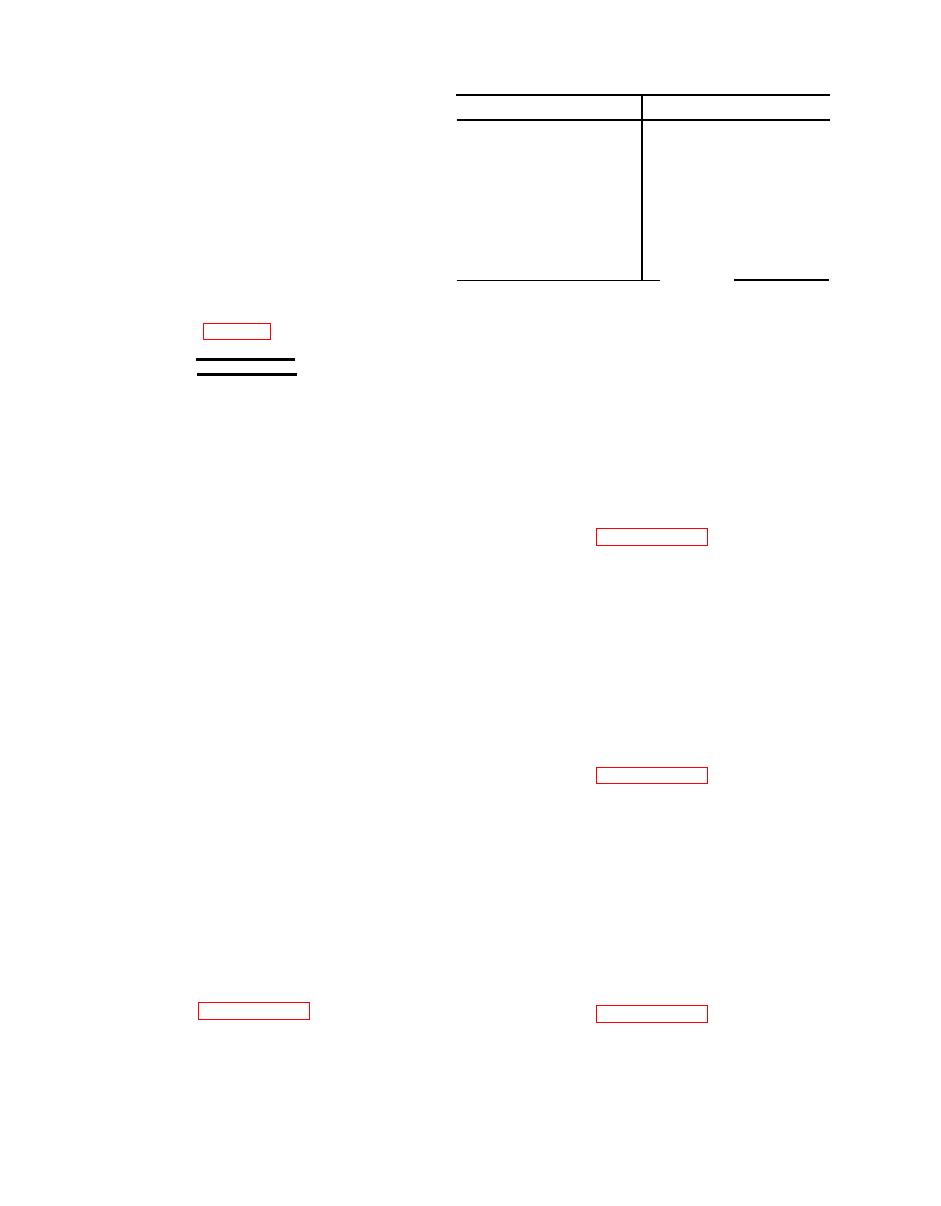

Type and Specification

Use

(5) Apply sealant in 1/8-inch minimum fillet.

I

Interior and exterior panel Epoxy Polyamide, MIL-P-

g. Corrosion Removal. Before a corroded area

surfaces and metal parts 23377,

can be refinished, the corrosion must be removed

primer

by such means as wire brushing (with corrosion-

Interior walls and ceilings Lacquer, Semigloss, MIL-L-

resistant wire brush), sanding, abrasive blasting,

52043, Color, White, Fed Std

finish coat

or application of corrosion-removing compounds.

27875

Floor finish coat

Durapox Type II Anti-Skid

The affected area must be free of dust, residue,

Covering, Gray

and cleaning compounds before refinishing. Refer

Exterior panel surfaces and Enamel Alkyd, Camouflage,

to following paragraph for paint refinishing in-

Forest Green, MIL-E-52798

metal parts finish coat

---------.

structions.

h. Paint Refinishing. Primers and paints used

for refinishing painted surfaces of the expandable

a. General, There are two foldout end walls

shelter are listed in table 3-6. The following general

contained in the expandable shelter. When these

procedure is recommended for refinishing.

end walls are fully unfolded into position, they

WARNING]

form the left and right end walls of the deployed

Paints are flammable. Use in a well-

shelter. The following paragraphs contain in-

ventilated area and remove all sources of

spection and repair information for the foldout

possible ignition.

end walls.

(1) Thoroughly clean surface to be painted.

b. Inspection. Check that all seals are secure.

Remove all traces of dirt, oil, corrosion, and loose

Check fan panel assembly. Check hinges and

paint.

fasteners for damage and ease of operation.

(2) If the surface to be painted is bare

Inspect surface for damage.

aluminum, apply conversion coating first. In the

c. Repair. Refer to shelter body repair in-

case of ferrous parts, apply metal conditioner,

structions given in paragraph 3-16.

Specification MIL-M-10578. Allow coatings to dry

thoroughly before applying primer.

3-19. Foldout Roof Panels.

NOTE

a. General. There are two foldout roof panels

Drying times for primers and paints vary ac-

contained in the expandable shelter. When these

cording to temperature and humidity.

roof panels are fully unfolded into position, the y

(3) Mix and apply a uniform coat of primer in

form the left and right side roof section of the

accordance with MIL-C-22751D.

deployed shelter. The following paragraphs contain

NOTE

inspection and repair information for the foldout

Allow primer to dry thoroughly before applying

roof panels.

finish coat.

b. Inspection. Check that all seals are secure.

(4) Mix and apply two separate, uniform coats

Check hinges and fasteners for damage and ease of

of finish coat, making certain there are no sags or

operation. Inspect surface for damage.

runs. Be sure first coat is dry before applying

c. Repair. Refer to shelter body repair in-

second coat.

structions given in paragraph 3-16.

a. General. There are four swingout walls

a. General. There are two foldout floor panels

contained in the expandable shelter. When these

contained in the expandable shelter. When these

walls are fully unfolded into position, they form

floor panels are fully unfolded and into position,

the four left and right end panels of the deployed

they form the left and right side floor sections of

shelter. The following paragraphs contain in-

the deployed shelter. The following paragraphs

spection and repair information for the swingout

contain inspection and repair information for the

walls.

foldout floor panels.

b. Inspection. Check that all seals are secure.

b. Inspection. Check that all seals are secure.

Inspect surface for damage and corrosion. Check

Check hinges and fasteners for damage and ease of

latches for damage and ease of operation.

operation. Inspect surface for damage.

c. Repair. Refer to shelter body repair in-

c. Repair. Refer to shelter body repair in-

structions given in paragraph 3-16.

structions given in paragraph 3-16.