TM 10-5410-224-14

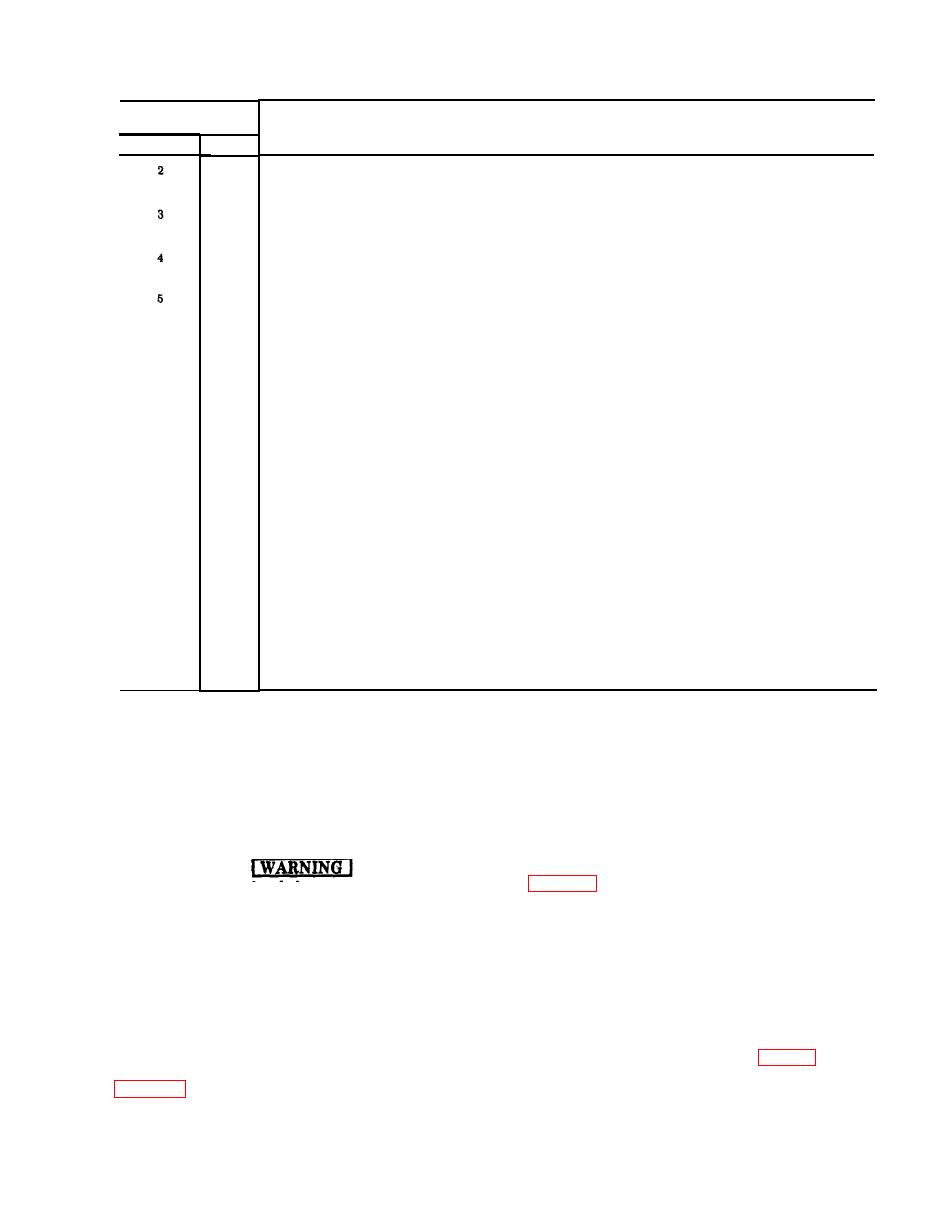

Table 3-3. Organizational Preventive Maintenance Checks and Services Continued

M-Monthly

Q-Quarterly

Interval and --

Item to be Inspected

Procedure

Seqence No.

M

Q

FOLDOUT ROOF AND FLOOR PANELS

Check that all seals are secure. Check hinges and fasteners for damage and ease of operation. Inspect

surface for damage.

FOLDOUT END WALLS

Check that all seals are secure. Check fan panel assembly. Check hinges and latches for damage and

for ease of operation. Inspect surface for damage.

PERSONNEL AND CARGO END PANELS

Check that all seals are secure. Check operation and condition of exterior light, Inspect surface for

damage. Check safety cables and latches. Check lifting and towing eyes for condition and security.

PERSONNEL AND CARGO DOORS

Check security and condition of door hinges. Check operation and security of door handles and

linkage. Check doors for proper sealing. Inspect door surface and vents for damage. Check security of

steps to roof.

6

CENTER STRUCTURE ROOF AND FLOOR PANELS

Check that all seals are secure. Inspect surface for damage. Check roof drop pad. Check roof handle

and plate.

7

POWER ENTRANCE PANEL

Check condition of electrical connectors. Check for presence of dirt, rust, or corrosion. Check for

condition of grounding stud.

8

LEVELING JACKS

Check for mounting and general security of jacks. Lubricate jack screw in accordance with MIL-G-

23827. Check that ratchet operates freely.

9

ECU INSTALLATION KIT AND SHELTER REPAIR KIT

Check for completeness and general condition.

10

COMPLETE SHELTER

Check that expandable shelter is level. Check that modifications have not been made that prevent

complete shelter deployment or stowage. Check that ECU's are properly installed. Check all markers

for legibility.

11

SHELTER INTERIOR

Check shelter floors, walls, and ceiling for general condition and security. Check electrical wiring,

receptacles, and outlets for security of attachment and condition. Check ventilation fans for proper

installation, general condition, and operation. Check ceiling lights and receptacles for proper in-

stallation, general condition, and operation.

12

CIRCUIT BREAKER PANEL

Check circuit breakers and switches for security of attachment and proper mechanical operation.

Check general conditions of structure and door. Check condition of wires and connections.

Section VI. ORGANIZATIONAL MAINTENANCE TROUBLESHOOTING

3-13. General.

tests or inspections which help to determine

probable causes and corrective actions to take. The

This section contains organizational maintenance

tests or inspections and corrective actions are to be

troubleshooting information for locating and

performed in the order listed in the table.

correcting most of the operating troubles which

b. All malfunctions that occur, tests or in-

may develop in the expandable shelter.

spections, and corrective actions cannot be listed

in table 3-4. If a malfunction is not listed or is not

The expandable shelter contains voltages

corrected by listed corrective actions, the ap-

that are dangerous if contacted. Take

propriate supervisory personnel should be notified.

precautions

appropriate

when

c. Unless otherwise noted, when troubleshooting

troubleshooting. Before performing con-

the operation of the expandable shelter, the

tinuity checks or replacing electrical

switches, controls, and circuit breakers must be

components, make certain electrical power

placed in proper operating positions and power

is completely disconnected from the circuit

must be properly connected.

involved,

NOTE

3-14. Troubleshooting Table.

Unless otherwise noted, all circuit breakers and

a. Each malfunction for an individual com-

switches celled out in troubleshooting table 3-4 are

located on circuit breaker panel.

ponent, unit, or system is listed in troubleshooting