TM 9-2330-390-14&P

4-59. MINOR BRAKE ADJUSTMENT.

This Task Covers: Adjustment

Initial Setup:

Tools/Test Equipment:

• General mechanic’s tool kit (Item 30, Appendix G)

• Hydraulic jack, 12 ton (Item 17, Appendix G)

• Trestle (Item 32, Appendix G)

NOTE

Dolly set hydraulic lifting system may be used Instead of a hydraulic jack to raise dolly

set wheels off ground (see paragraph 2-21).

ADJUSTMENT

1.

Chock wheel on side not being adjusted.

2.

Raise dolly set on side to be adjusted until wheel is off ground. Support dolly set in raised position with trestle.

3.

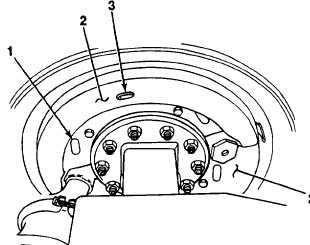

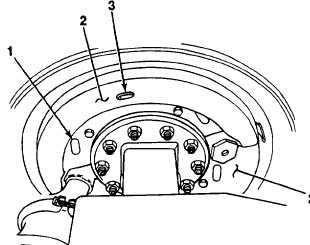

Insert feeler gage into access slots (3) in top and

bottom dust shields (2). Check brakeshoe

lining-to-brakedrum clearance at top of each

brakeshoe. Total clearance for both brakeshoes

should not exceed 0.090 in. (2.3 mm). Individual

brakeshoe clearance should not exceed 0.050 in.

(1.3 mm) across width of shoe.

4.

5.

If clearances measured in step 3 are as speci-

fied, brakes are properly adjusted. If clearances

are not within specification, proceed to step 5.

Remove plug from access slot (1). Insert long,

thin screwdriver into access slot until it contacts

starwheel on adjusting bolt. Turn starwheel coun-

terclockwise to reduce clearance or clockwise to

increase clearance.

6.

Repeat step 3. If clearance is within specifica-

tion, install plug in access slot (1).

7.

Repeat steps 5 and 6 to adjust for correct clearance on other brakeshoe on same wheel.

8.

Rotate brakedrum one full turn by hand. If drag is apparent, repeat steps 5 through 7.

9.

Repeat steps 1 through 7 for other wheels.

10.

Remove trestle and lower dolly set wheel to ground.

4-130