TM 10-5410-223-14/1

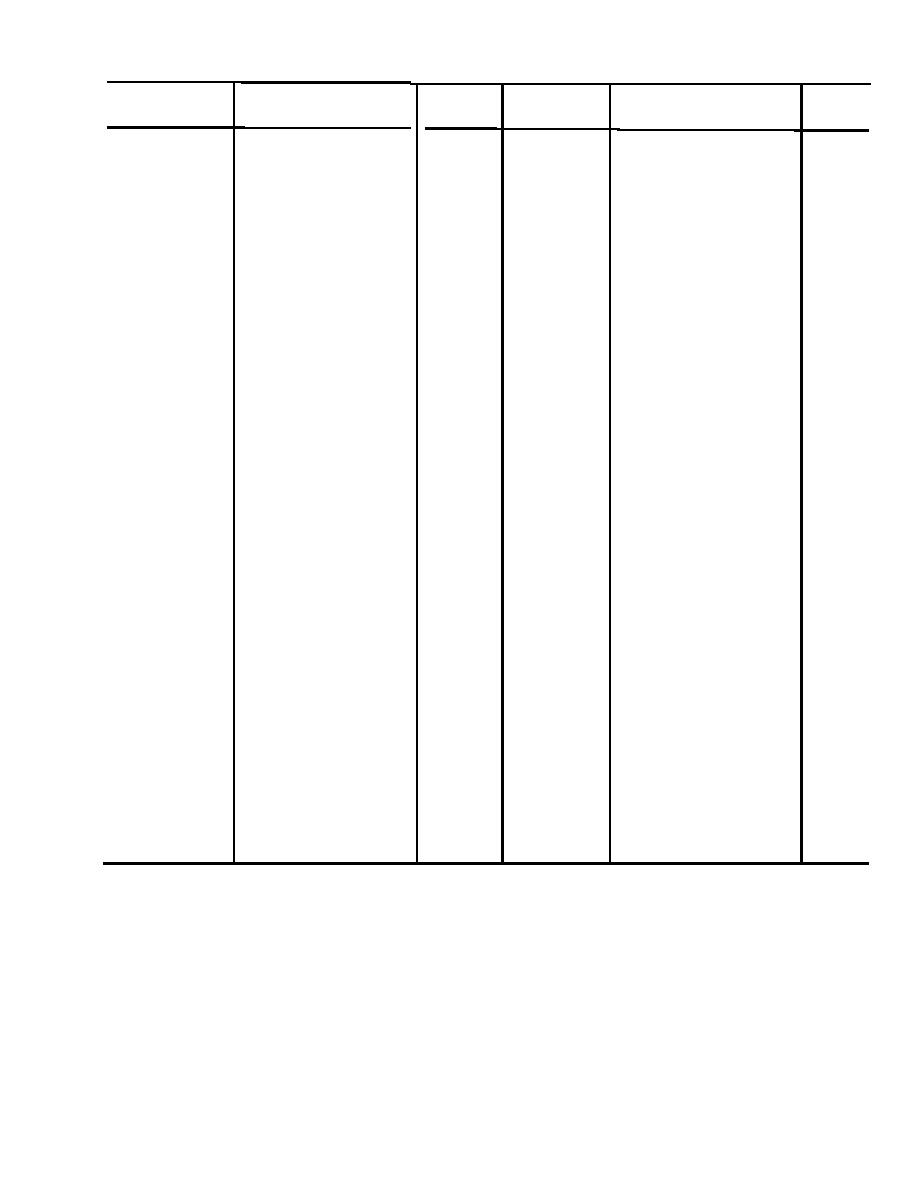

Table 4-3. Blind Rivet Selection Chart

Nominal

rivet

Hole size and

Rivet

diameter

drill number

Diameter

Length

Grip range

No.

32

3/32

.020

.125

0.096

.100

.212

(0.2438 cm

(0.2381 cm)

(0.0508 cm

- 0.3175 cm)

- 0.254 cm)

(0.5385 cm)

34

.126

.250

#41

.094

.337

(0.3200 cm

- 0.635 cm)

(0.2388 cm)

(0.8560 cm)

.020

.062

41

.170

(0.0508 cm

- 0.1575 cm)

(0.4318 cm)

.063

.125

42

.232

(0.1600 cm

- 0.3175 cm)

(0.5893 cm)

.126

.187

43

.294

- 0.4750 cm)

(0.3200 cm

(0.7468 cm)

44

1/8

.188

.250

.128

.132

.357

(0.3251 cm

(0.4775 cm

- 0.635 cm)

- 0.3353 cm)

(0.3175 cm)

(0.9068 cm)

45

.251

.312

#30

.125

.419

(0.6375 cm

- 0.7925 cm)

(0.3175 cm)

(1.0643 cm)

.375

46

.313

.481

(0.7950 cm

- 0.9525 cm)

(1.2217 cm)

48

.376

.500

.628

- 1.27 cm)

(0.9550 cm

(1.5951 cm)

.020

.125

52

.254

(0.0508 cm

- 0.3175 cm)

(0.6452 cm)

.126

.187

.160

.164

.316

(0.3200 cm

- 0.4750 cm)

(0.4064 cm

- 0.4166 cm)

(0.8026 cm)

.250

54

5/32

.188

#20

.156

.379

(0.4775 cm

- 0.635 cm)

(0.3969 cm)

[0.3962 cm)

(0.9627 cm)

56

.251

.375

.504

- 0.9525 cm)

(0.6375 cm

(1.2802 cm)

.500

.376

.629

- 1.27 cm)

(0.9550 cm

(1.5977 cm)

.125

62

.020

2.77

- 0.3175 cm)

(0.0508 cm

(0.7036 cm)

64

.250

.126

.192

.196

.402

- 0.635 cm)

(0.4877 cm

(0.3200 cm

- 0.4978 cm)

(1.0211 cm)

.375

66

3/16

.251

#11

.187

.527

(0.6375 cm

- 0.9525 cm)

(1 .3386 cm)

(0.4762 cm)

10.4750 cm)

68

.376

.500

.652

- 1.27 cm)

(0.9550 cm

(1.6561 cm)

.625

610

.501

.777

- 1.5875 cm)

(1.2725 cm

(1.9736 cm)

.750

.626

.902

- 1.905 cm)

(1 .59 cm

(2.2911 cm)

.250

.257

.125

84

.261

.447

(0.6528 cm

- 0.635 cm)

- 0.6629 cm)

(0.3175 cm

(1.1354 cm)

1/4

.375

86

F

.251

.250

.572

(0.635 cm)

(0.6375 cm

- 0.9525 cm)

0.635 cm)

(1 .4529 cm)

88

.376

.500

.697

- 1.27 cm)

(0.9550 cm

(1.7704 cm)

.947

.626

.750

812

(1 .59 cm

(2.4054 cm)

- 1.905 cm)

(a) Hold parts to be riveted tightly together

seat rivet and to aid in avoiding sheet or other part

with epoxy or other satisfactory method.

separation.

(b) Insert proper rivet in hole and apply with

(d) Pull rivet until stem breaks.

gun (supplied with repair kit) by inserting stem head

(e) Installed blind rivets shall be checked per

of rivet in bottom slot in gun pulling head

paragraph (3) below, before proceeding.

(nosepiece).

(f) Trim the broken stem flush with the rivet

head.

NOTE

Wet all rivets with sealant (EC 776, 3M Co., or

(g) Firmly press on the installed rivet to

equivalent) before installation.

assure tightness.

(4) Inspection of installed rivets. Installed

(c) Hold gun at right angle to work. Push

rivets shall be inspected as follows:

gun against work with just enough force to firmly

4-59