TM 10-5410-221-14/1

(a) Position parts to be sewn together and

sides, and bottom of the air-lock chamber. The body

temporarily secure the position of the parts. Sew parts

assembly consists of a fabric body with various fabric

together (fig. 9-6) with five to nine stitches per inch (2.54

attachment and reinforcing components installed.

b. Rernoval. Removal of fabric body assembly

cm). Use single needle or double needle stitching as

noted on removed parts.

consists of removing the other components of the air-

lock chamber as described in paragraphs 9-2 and 9-3.

c. Disassembly. Disassemble fabric body assembly

NOTE

as required for replacement of damaged components as

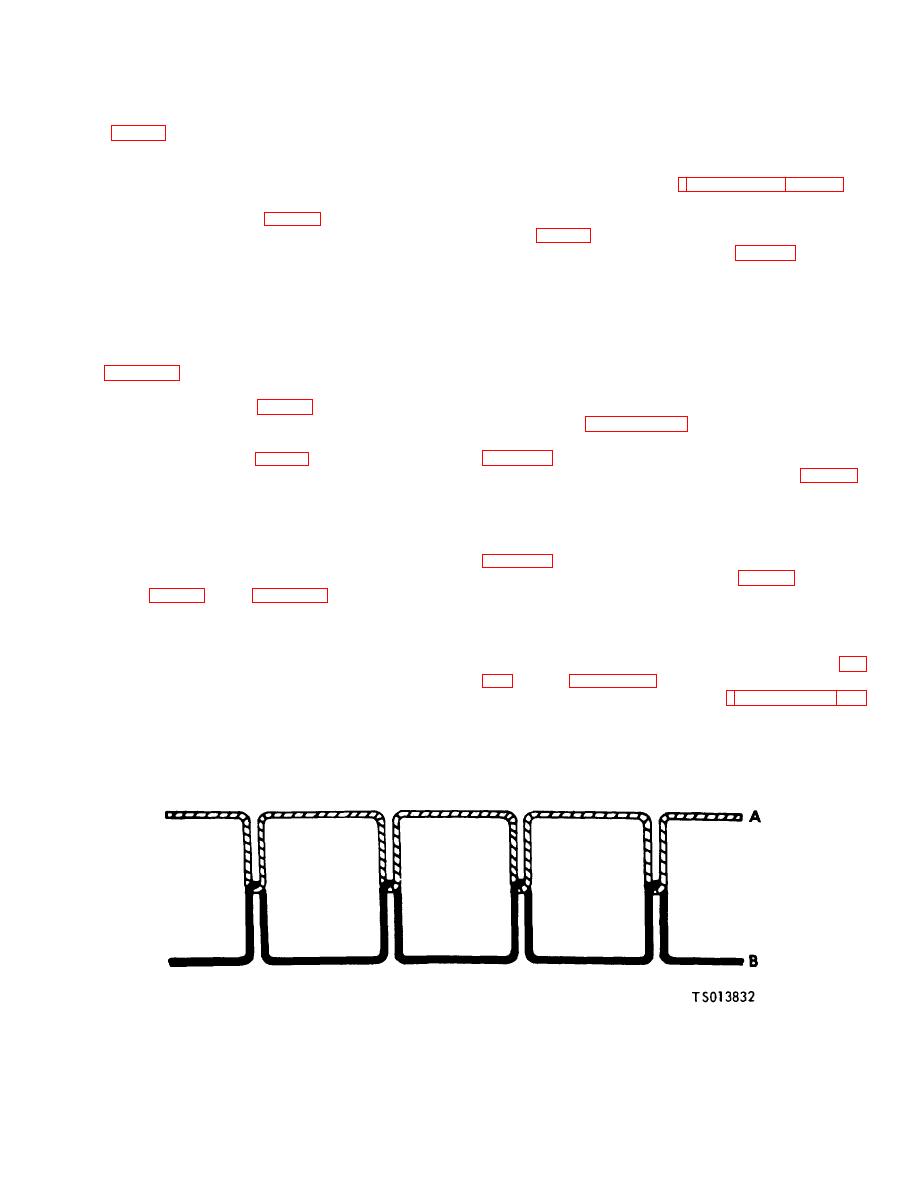

This type of stitch 301 (fig. 9-6) shall be

follows (fig. 9-7).

formed with two threads: one needle

(1) Untie and remove cord (1, fig. 9-7). Peel tie

thread, A, and one bobbin thread. B. A

patch assemblies (2), bow holding snap assemblies (3),

loop of thread A shall be passed through

light and fixture patch assemblies (4), and reinforcing

the material and interlaced with thread

patches (5) from body cloth (11) as described above.

B. Thread A shall be pulled back so that

(2) Cut stitches and remove tent pin patch

the interlacing shall be midways

assemblies (6), ground aprons (7), electrical patch

between surfaces of the material or

assemblies (8), slider half of zippers (9), and hook fabric

materials being sewn.

fastener tape (10) from body cloth (11) as described

above.

air-lock chamber components.

d. Repair. Repair damage to fabric body assembly

(2) Cement end panel (12, fig. 9-3) to door assembly

as described in paragraph 5-7.

(13) and cement reinforcing tape (7) to end panel (12)

e. Assembly. Assemble fabric body assembly using

and door assembly (13).

(3) Install gaskets (4, 5, 6, fig. 9-3) on valve (3) using

(1) Install hook fabric fastener tapes (10, fig. 9-7),

adhesive (140, Dow Corning Corp., Midland, Michigan).

slider half of zippers (9), electrical patch assemblies (8),

Install anti-back draft valve (3) on door assembly (13)

ground aprons (7), and tent pin patch assemblies (6) on

(with valve counter-weight up) and secure with

body cloth (11) and secure by sewing as described

lockwashers (2) and screws (1).

above, using size F-F olive green thread, and observing

(4) Position blackout curtain components together

and secure by sewing as described above.

f. Installation. Install end panel and door

(2) Cement reinforcing patches (5, fig. 9-7), light and

fixture patch assemblies (4), bow holding snap

assembly (10, fig. 9-1) using figure 9-1 as a guide and

assemblies (3), and tie patch assemblies (2) on body

observing the following.

cloth as described above. Tie cord (1) in tie patch

(1) Install blackout curtain assemblies over door

assemblies (2).

assembly windows as described above.

(2) Engage and close zipper between end panel and

door assembly (10) and fabric body assembly

installation procedures described in paragraphs 9-2 and

(10) and fabric body assembly (11).

9-3.

9-4. Fabric Body Assembly

a. General. The fabric body assembly provides top,

Figure 9-6. Stitch Type 301 (TS 013832)

9-8