TM 10-5410-221-14/1

c. Repair. Check valve is not reparable. Remove and

assemblies to serviceable condition, replace the tube

assembly.

replace defective valve only.

d. Installation. Install check valve in reverse order of

(2) Inspect mounting brackets for damage and

misalignment.

If possible straighten any bent or

removal (para 4-42).

misaligned brackets by means of a padded vise, pliers,

10-5. Water Supply and Drain Tube Assemblies

or hammer. Repaint bracket assemblies by applying

(Water Tunnel)

primer and allowing to dry and painting with paint

a. General. The water and drain tube assemblies are

conforming to Federal Standard 595, Color Chip 34087.

used to supply hot and cold water to the shelter and

d. Installation. Install the water supply and drain tube

drain waste water from the shelter; They consist of

assemblies in reverse order of removal, and observe the

stainless steel tubes with flared ends and equipped with

following:

nuts and sleeves.

(1) Use new packings at required fittings.

b. Removal. Remove the supply and drain tube

(2) Pot all tube assemblies which enter the shelter

assemblies according to figures 10-1 and 10-2

using

RTV-731,

Dow

Corning Corp., Midland,

c. Repair and Overhaul. Repair or overhaul the

Michigan, or equivalent.

shelter supply and tube assemblies as required to return

(3) Torque all fittings using good shop practice.

to a serviceable condition as follows:

e. Test. Test the water system and vacuum plumbing

(1) Inspect all tube assemblies for damaged

for leaks as follows:

threads, nicks, dents, bent tubes or burrs. If possible,

(1) Install and tighten all nuts, caps, and plugs on

dress all nicks and burrs with emery cloth

water line and vacuum stubs extending, from water box

assuring that enough wall thickness of tube remains to

into shelter.

assure sufficient strength. Minor dents in the tube

(2) Install and tighten all nuts, caps, and plugs in

assembly are acceptable so long as the function or fit of

plumbing outlet box of shelter.

tubes is not affected. Dress minor damage to threads

(3) Connect air supply (60 PSIG)(4.218 kg per sq

with emery cloth and then pressure check to assure that

cm) to "cold water in" and check connections for leaks.

there are no leaks present. Minor bent tubes are

(4) Connect air supply (60 PSIG) (4.218 kg per sq

acceptable as long as function or fit is not affected. If

cm) to "hot water in" and check connections for leaks.

possible straighten tubes using a tube bending tool or

clamping in a padded vise, or by hand. If methods listed

above

cannot

return

the

tube

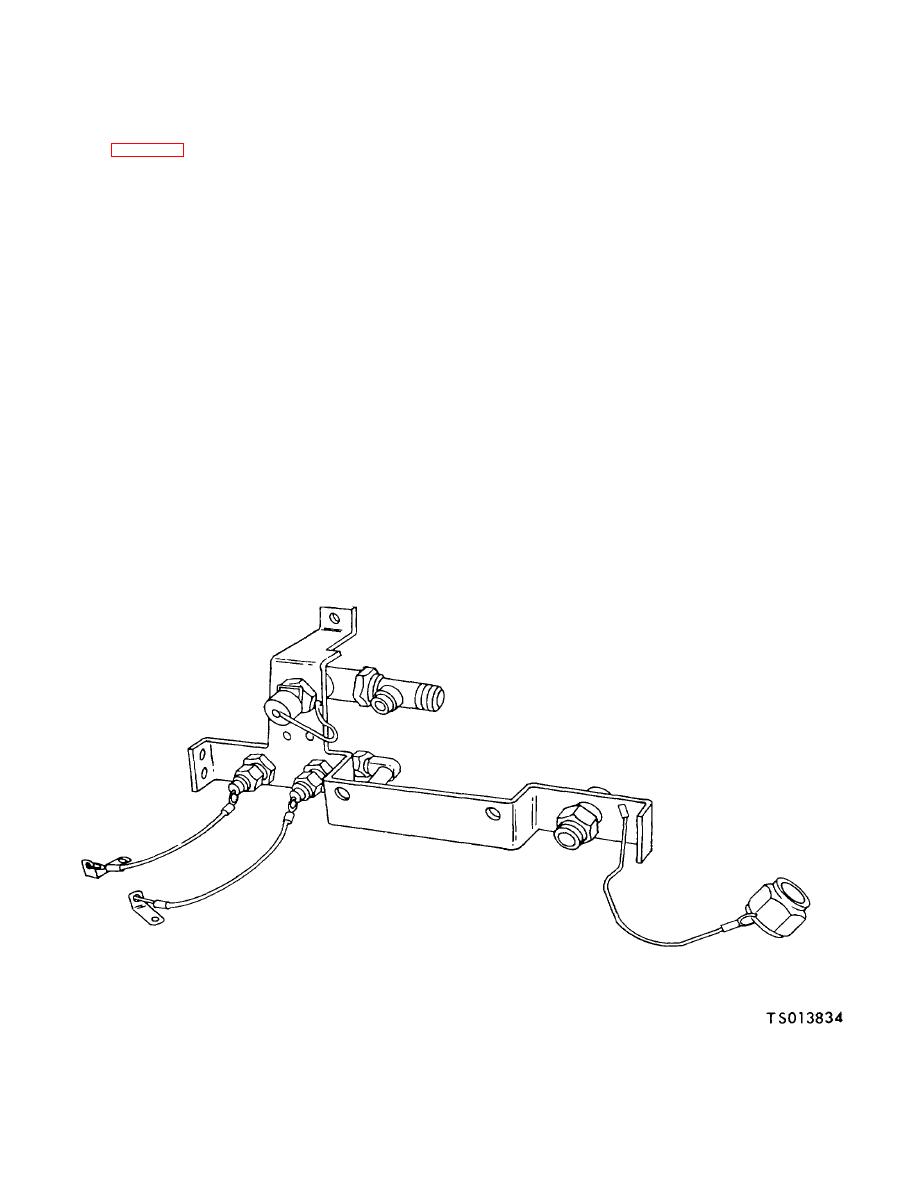

10-1. Plumbing System, Installation and Disassembly (Sheet 1 of 2) (TS 013834)

10-2