TM 55-8115-200-23&P

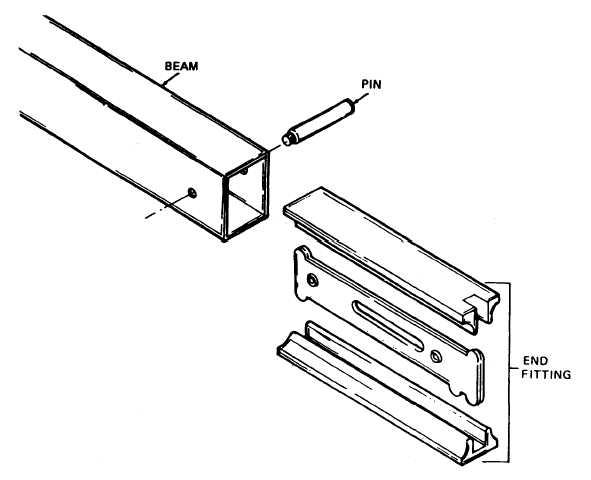

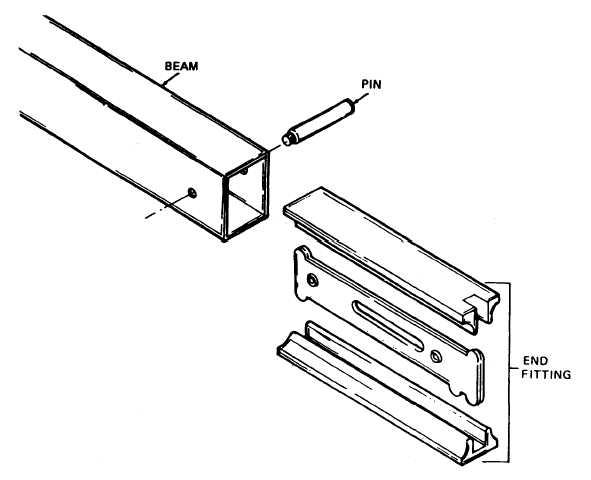

2-17. Load Bracing System. The cargo load bracing

system consists of a series of beam assemblies sup-

ported by vertical and horizontal rails. (See fig. 1-3.)

An end fitting assembly (fig. 2-4) installed in each

beam engages with the rails to provide the means of

beam support. Maintenance of the bracing system

consists of inspection of the complete system and

replacement and repair of the beam assemblies.

a. Inspection. Inspect the general condition of

the mechanical bracing system. Assure that the

assigned number of load bracing beam assemblies

are present (see list on door). Horizontal rails will

be examined for attachment to sidewall and for

deformation that prevents proper attachment of

beam assemblies. Beam assemblies will be ex-

amined for distortion and condition of end fittings

that prevent proper engagement in the rails.

b. Beam Replacement and Repair. Repair of

the beam assembly consists of straightening the

beam and replacement of the end fittings. Replace

end fittings as follows:

(1) Using a suitable punch, straighten the

crimped end of the pin (see fig. 2-4) and drive the

retaining pin from the beam assembly.

(2) Remove beam assembly with end fitting and

remove end fitting from beam.

(3) If necessary, straighten any damaged area

of the beam.

(4) Install replacement end fitting in beam and

install retaining pin.

(5) Using a punch, peen end of pin to secure in

beam.

(6) Install beam assembly into container.

Figure 2-4. Load Bracing Beam Assembly.

2-6

Change 4