TM 55-8115-200-23&P

2-13. Water Test After Repair. After any major

repair to an empty container, a stream of water from an

O.5-inch nozzle at 15 psig shall be applied to all joints and

seams. No water entry into container is permissible after

repair.

2-14. Corner Posts, Comer Fittings, and Rail

Members. Inspect the condition of the comer posts, cor-

ner fittings, and structural rail members. Containers having

comer posts or rails torn, distorted, and kinked, or broken/

cracked fittings, are unserviceable and will be rejected for

use. Corner posts having a small vertical dent are accept-

able if it does not exceed 3/4 inch in depth and 12 inches

in length providing the post/corner fitting joint is not

affected. If deformation of the container configuration is

evident, dimensions must be checked. The over-all dimen-

sions and the variation of diagonal distances between

opposite corner fittings must be within tolerances as indi-

cated in paragraph 1-8.

2-15. Floor. The container floor consists of a total of

eight wooden planks mounted longitudinally on floor

crossmembers. In containers serial numbered less than

12000, a metal threshold plate is installed across the

entrance to the container and a twelve inch (30.5 cm)

aluminum alloy kick plate extends around interior of the

container adjacent to the floor. The threshold and side kick

plates are absent in containers serial numbered 12000 and

higher. Maintenance of the floor group consists of inspec-

tion as follows;

a. Inspect floor to ensure it is tight and free of holes.

b. Inspect the floorboards, crossmembers, and

threshold plate for warps, breaks or any similar damage.

c. Inspect the kick plate for security and excessive

damage.

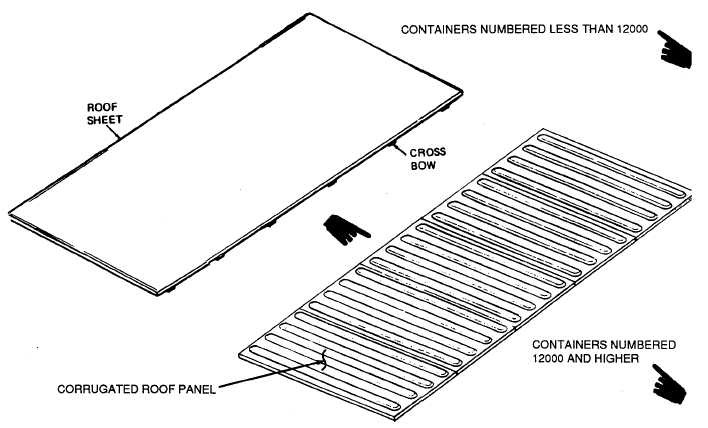

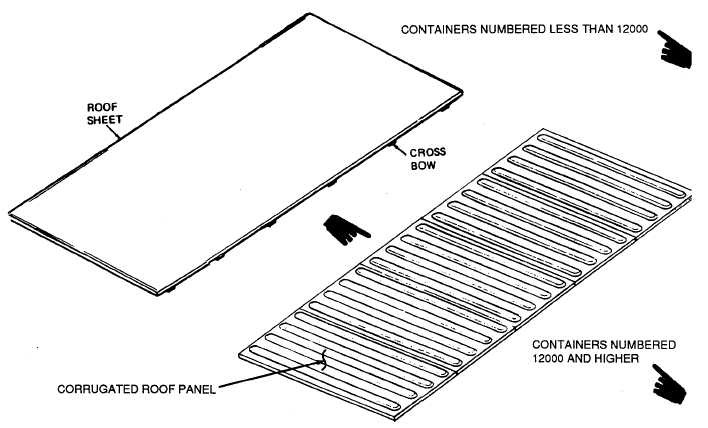

2-16. Roof. On containers numbered less than 12000,

the container roof consists of five sections of sheet steel

attached to the roof cross bows to make one complete

assembly. Maintenance of the roof bows consists of inspec-

tion for bends and cracks. Minor bends to the bows will be

accepted as long as there are no cracks. If the bows are bent,

but not cracked, they may be straightened back into posi-

tion. They must not be a safety hazard and must not impede

loading. Ensure that the welds are intact. (See fig. 2-3.)

Containers numbered 12000 and higher have five sheets of

corrugated metal welded directly to the top side rails.

Maintenance of the roof in either case consists of inspec-

tion for holes, tears and punctures.

Figure 2-3. Container Roof Assembly.

Change 42-5