TM 10-5410-223-14/1

CHAPTER 3

OPERATOR'S

MAINTENANCE

INSTRUCTIONS

Section I. LUBRICATION INSTRUCTIONS

NOTE

3-1. General Lubrication Instructions

Oil base lubricants shall not be used for floor and

a. Lubrication shall consist of lubricating zipper

ceiling hinges.

of the air lock adapter and air lock chamber with

c. After every lubrication operation, remove any

zipper lubricant.

excess lubrication from the point of application.

b. Lubricate all moving parts every 30 days or

Keep all areas, not requiring lubrication, clean from

before administrative storage.

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

recorded together with the corrective action taken,

3-2. General

on DA Form 2404 (Equipment Inspection and

To ensure that the shelter is ready for use at all

Maintenance Worksheet) at the earliest possible

times, it must be inspected systematically so that

opportunity.

defects may be discovered and corrected before they

result in serious damage or failure. The necessary

3-3. Preventive Maintenance Checks and Services

preventive maintenance services to be performed are

Preventive maintenance checks and services which

listed and described in paragraph 3-3. Defects

must be performed by operator/crew is contained in

discovered during use of the shelter will be noted for

Table 3-1. The item numbers are listed consecutively

future correction, to be made as soon as use is

and indicate the sequence of minimum inspection

discontinued. Stop use immediately if a deficiency is

requirements. Refer to Table 3-1 for the daily

noted which would damage the shelter if use were

preventive maintenance checks and services.

continued. All deficiencies and shortcomings will be

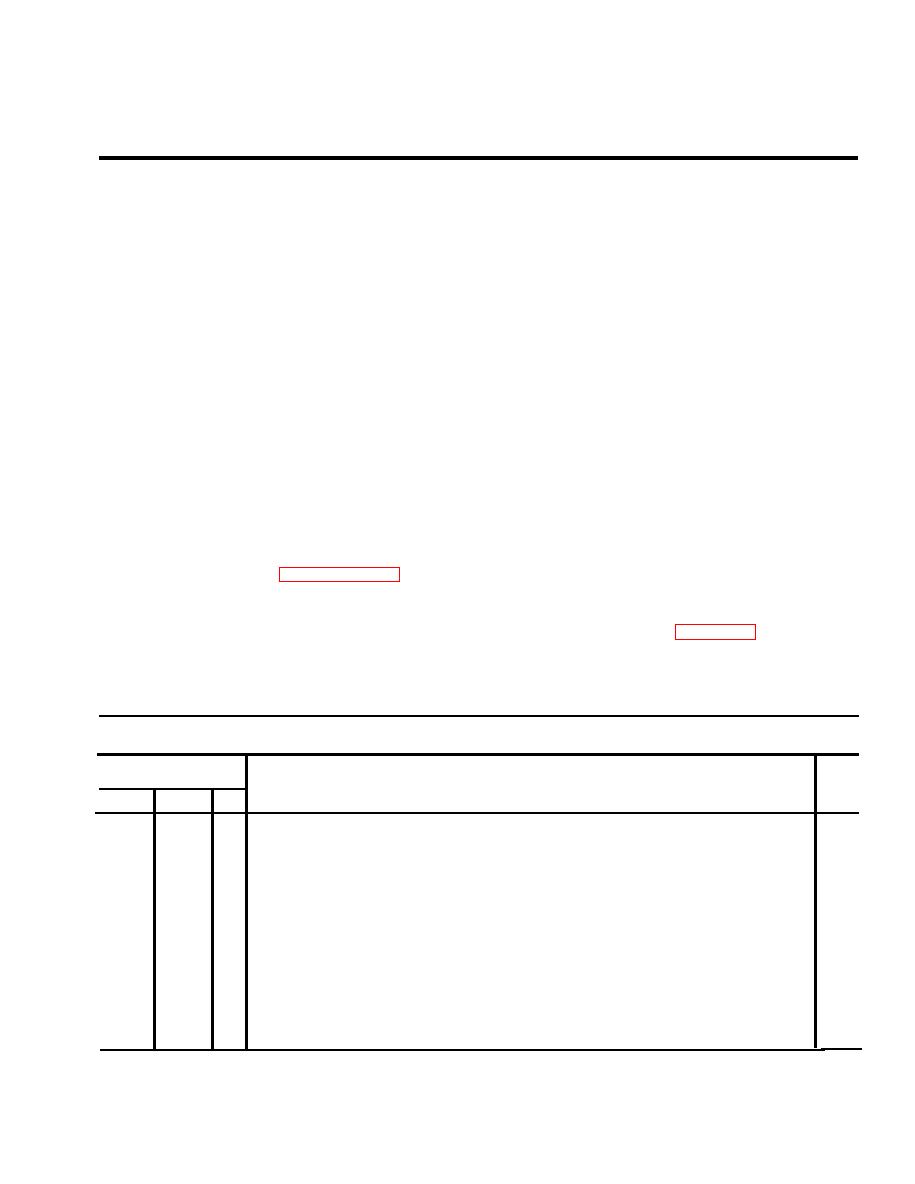

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services.

B--Before Operation

D--During Operation

A--After Operation

Time Required: .7

Time Required: .7

Interval and

Work

sequence no.

Item to be inspected

time

(M H)

procedure

A

B

D

0.2

9

FABRIC ENCLOSURE (INSIDE & OUTSIDE)

1

Visually check fabric enclosure for wear at seams, for broken stitches, for holes, for weak

spots, or other damage to fabric.

0.1

10

ZIPPERS

7

2

Visually check zippers on the air lock adapter and air lock chamber for missing teeth, un-

stitched seams or other damage.

0.1

11

FABRIC FASTENER TAPE

3

Visually check for damaged and unstitched seams.

0.1

12

DOOR

4

Check door and anti-backdraft valve for smooth operation.

0.1

13

WALLS

5

Visually check shelter walls for damage.

0.1

14

8

6

LEVELING JACKS

Visually check leveling jacks for sinking (frequently during rainy conditions) and floor to

insure it is level.

3-1