TM 10-5410-221-14/1

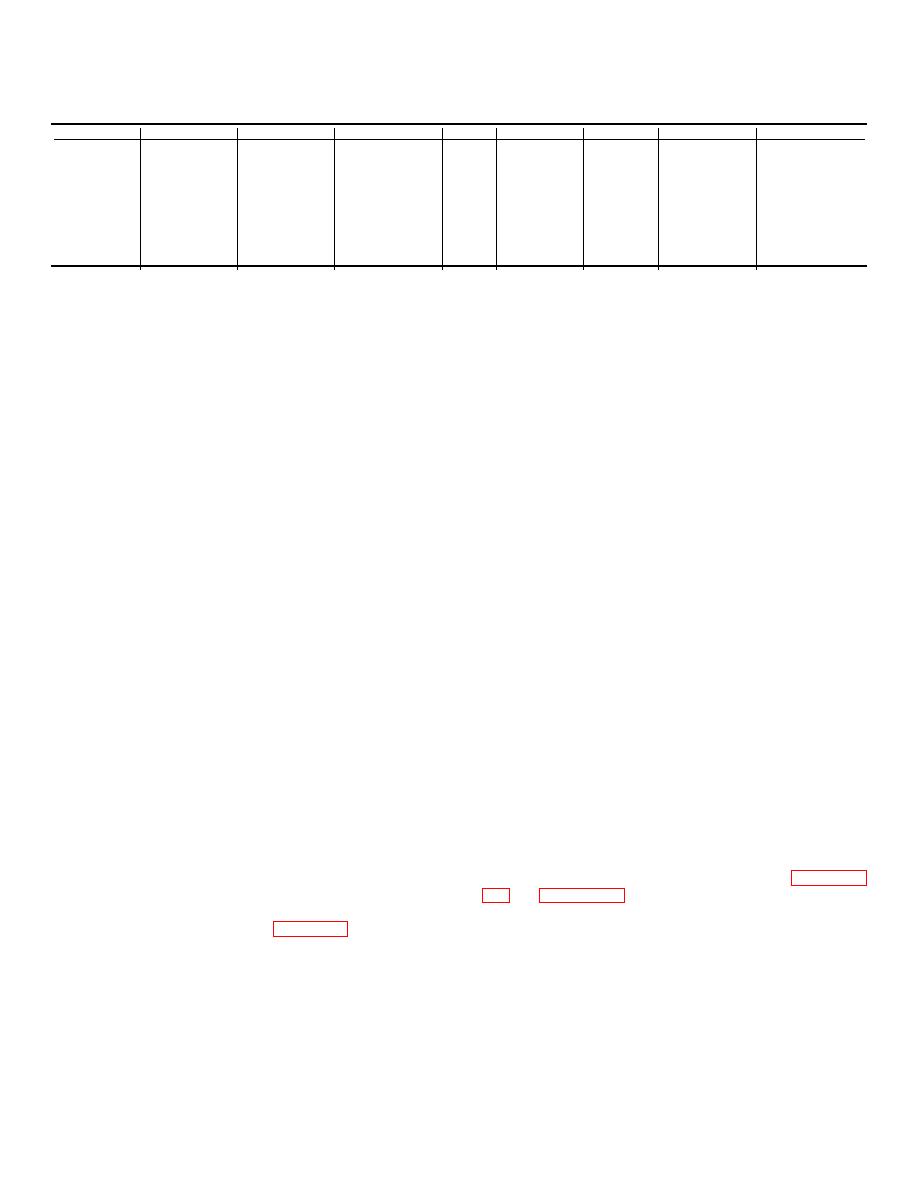

Table 4-4. Finishing Systems

Type

Surface

Pretreatment

Primer

Coats

Intermediate

Coats

Finish

Coats

A

Metal

MIL-P-153287/

TT-E-485

1

-

TT-E-485

1

2/5/6/8/

1/2/3/4/5

Wood

MIL-S-13518

TT-P-636 6/

1

TT-E-529

1

Type 1

3/4/

B

Metal

MIL-P-153287/

MILP-12742

1

MILP-12742

1

TT-E-522

1

Type I

C

Metal

MIL-P-153287/

TT-E-4855/

1

D

Metal

MIL-P-153287/

MILP-85859/1

TT-E-529

2

E

Metal

MILP-513287/

MIL-P-85895/1

MIL-,-52043

2

near as possible the original finish requirement. The

also to the floor fabric.

color of touched up areas shall be reasonably close to

(5) Press the patch over the trimmed damaged area

that of the surrounding area.

and work out any trapped air bubbles.

c. Repair to Honeycomb Panel with Damage to Both

NOTE

Surfaces. Damage to panel which penetrates both

The patch should be laid on gradually.

surfaces shall be repaired using .procedure given in

one side on the other, or from the

paragraph b. above. Both facings shall be repaired.

center to the edges. to minimize the

d.

Repair to Fabric Floor Covering.

Repair

possibility of entrapped air. Use two

damaged or worn floor fabric as follows: (I) With a sharp

men to apply patches larger than four

knife cut a square area from around damaged or worn

inches. (10.16 cm) one to hold the top

section.

edges up and away from prepared

NOTE

surface while the other starts applying

If aluminum facing or honeycomb core

patch evenly and smoothly from the

is damaged, repair using procedures

bottom. This will prevent the patch

given in paragraph b., steps (I)

from wrinkling and forming air

through (5), (9) and (10). Do not

bubbles.

install doubler plate in order to assure

(6) Cover the seams of the repaired area with

a smooth surface.

mylar tape (supplied with repair kit):

(2) Peel away damaged flooring.

Use the

e. Repair to Damaged Honeycomb Panel Edging

removed flooring as a template and cut a new section

(Closeouts). Repair damaged panel edging as follows:

using the flooring fabric supplied in the repair kit.

(1) Remove the damaged phenolic edging with a

(3) Thoroughly clean the repair area with emery

sharp knife to cut away from honeycomb core, using

cloth and a clean, lint-free cloth soaked in methyl-ethyl-

care to prevent damage to honeycomb core and

ketone.

aluminum facing edge.

(4) Apply a thin coat of the one part adhesive,

(2) Cut a section of phenolic edging the same

supplied with the repair kit, to the floor surface and

size as the damaged area and apply a thin coat of the

two ports adhesive to the phenolic edging back.

(3) Press the edging firmly in place and allow to

cure for a minimum of 8 hours.

Section XIV. MAINTENANCE OF EXPANDABLE SHELTER REPAIR KIT

4-51. General

4-52. Replacement of Components of Repair Kit

This section provides instructions for replacement of

Components of the repair kit should be replaced as

those items considered as part of the expandable shelter

soon as possible after use in order to maintain a

repair kit. The Components of the repair kit are stowed

complete kit at all times. See tabulated data. paragraph

in a plywood box assembly 24 inch x 16 inch x 16.5 inch

(60.96 cm x 40.64 cm x 41.'91 cm) and are listed in the

the repair kit.

Tabulated

Data,

1-6.

4-95