TM 9-2330-390-14&P

Change 4 5-41

5-10.

HYDRAULIC LIFT CYLINDER REPAIR (M1022A1 WITH SIDE LIFT KIT) (Con't).

WARNING

•

Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective

goggles and gloves, and use only in a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open

flame or excessive heat. The solvent's flash point is 100°F-138°F (38°C-59°C). If

you become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts eyes, immediately wash your eyes and seek

medical attention.

•

Compressed air used for cleaning or drying purposes, or for clearing restric-

tions, should never exceed 30 psi (207 kPa). Wear protective clothing (goggles/

shield, gloves, etc.) and use caution to avoid injury to personnel.

1.

Clean all removed parts with dry cleaning solvent. Ensure that all traces of sealing compound and masking

tape have been removed. Dry thoroughly with compressed air.

2.

Inspect all components for cracks, breaks, bends, or corrosion. Inspect threaded parts for damaged

threads. Replace damaged components.

3.

Inspect butt and tube assembly, piston tube, and piston tube assembly for scoring, pits, corrosion, or burrs.

Replace damaged components.

NOTE

All components should be lightly coated with hydraulic fluid before assembly.

1.

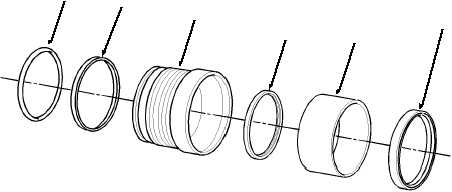

Starting with larger stage, install new backup washer (34) and new O-ring (33) to gland (25).

2.

Install new T-seal (35), DU bushing (36), and new wiper (37) in gland (25).

a.

CLEANING AND INSPECTION

b.

ASSEMBLY

33

34

25

35

36

37