TM 9-2330-275-14&P

4-39. POWER CLUSTER REPLACEMENT.

This Task Covers:

a. Removal

b. Installation

Initial Setup:

Equipment Conditions:

l Dolly sat parked on level surface with

handbrakes applied (para 2-2).

l Air reservoir draincock opened (para 4-43).

Tools/Test Equipment:

l General mechanic’s tool kit

• Common no. 1 shop set

Materials/Parts:

• Rags (Items 10, Appendix E)

• Antiseizing tape(item17 Appandix E)

a.

REMOVALI

NOTE

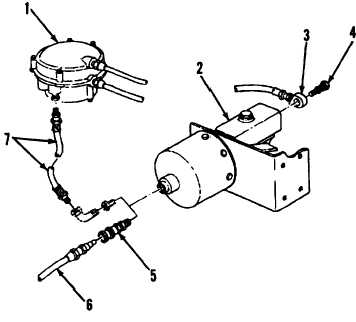

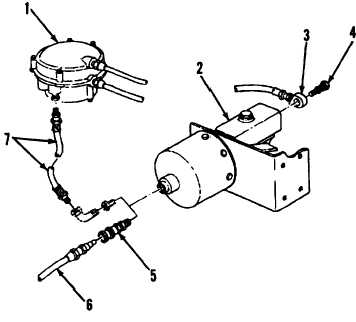

l Each dolly set has two power cluster assembles.

l Power cluster consists of master cylinder and air cylinder.

• For the M832 (SN J089-001 thru 159 and J017-160 thru 350), bracket is rotated

180 degrees.

1.

If removing power cluster at front dolly, disconnect air hose (7) from relay valve(1).

2.

If removing power cluster at rear dolly, disconnect air hose (6) from quickdisconnect fitting (5).

3.

Remove fluid passage bolt (4) and disconnect multiple connector (3) from master cylinder (2).

4 - 9 5