TM 10-5411-201-14

T.O. 35E4-178-1

4-42.

(cont)

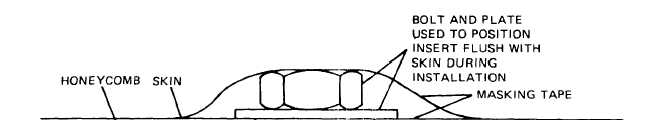

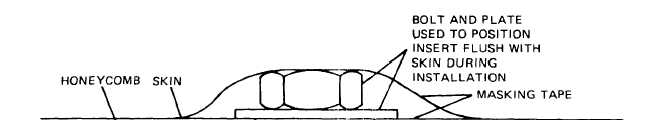

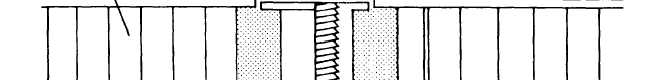

Prepare aluminum plate (Item 24,

Appendix E) approximately 1/8 in.

(3.2 mm) thick by 2 in. (50.8 mm) square with a center hole equal to bolt

thread outer diameter (replacement insert thread size).

p.

Install bolt through plate and into insert.

Hand-tighten insert

against plate.

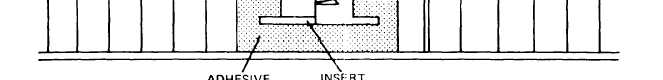

q.

Mix sufficient amount of adhesive (Item 1, Appendix E) in accordance

with manufacturer’s instructions.

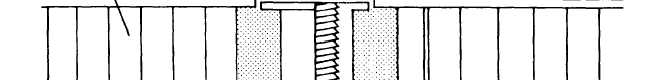

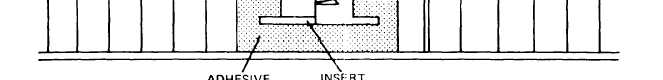

r.

Fill prepared hole completely with mixed adhesive.

Make sure there

are no air pockets.

s.

Force preassembled insert into filled hole with a threading motion

until plate is flush against skin.

t.

Clean excess adhesive (squeeze nut) from work area.

u.

Apply masking tape over bolt to maintain alignment during curing

cycle.

v.

Cure non-structural inserts for at least 4 hours at 75° F.

w.

Inserts on which there is structural dependency should be cured at

75° F for 72 hours.

x.

After cure, remove masking tape, bolt, and plate.

Y.

Clean skin as required.

z.

Refinish in accordance with paragraph 4-44.

4-182