TM 9-2330-390-14&P

4-272 Change 4

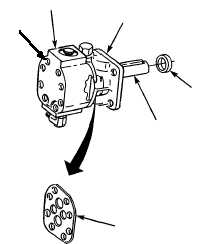

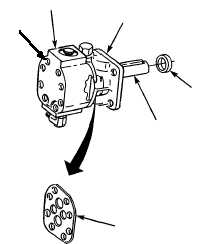

4-107. HYDRAULIC PUMP MAINTENANCE (Con't).

1.

Remove eight screws (22).

2.

Separate pump halves (23 and 24).

3.

Inspect seal/shim (26) for damage. Retain if

not damaged.

4.

Separate pump shaft (17) from pump half (24).

CAUTION

Use caution not to damage housing of

pump half.

5.

Remove seal (25) from pump half (24). Discard

seal

1.

Clean all removed components with a clean rag.

2.

Inspect all components for cracks, breaks, bends, corrosion, or damaged threads. Replace damaged com-

ponents.

1.

Lightly tap new seal (25) into pump half (24).

CAUTION

Use caution when inserting pump shaft into pump half. Damage to seal could result.

2.

Insert pump shaft (17) into pump half (24) and through seal (25).

NOTE

If a replacement seal/shim is required, obtain from seal kit P/N 2300622. Replace

seal/shim color for color, to ensure pump gear internal clearances are maintained.

3.

Assemble pump half (23), seal/shim (26), and pump half (24). Secure with eight screws (22).

4.

Torque screws (22) to 114-150 lb.-in. (13-17 N•m).

NOTE

Preformed packings should be lightly coated with hydraulic fluid before Installation.

1.

Install two new preformed packings (16) and elbows (2 and 14) on hydraulic pump (13).

NOTE

Hydraulic pump should be installed with inlet (suction) port at top and alined with

top of adapter. Access cover opening of adapter will also be facing up.

2.

Install hydraulic pump (13) on adapter (5) with four new lockwashers (20) and bolts (21).

3.

Coat pump shaft (17) with grease. Install hydraulic pump coupling half (18) on pump shaft with keyways

engaged. Tighten setscrew (19).

b.

DISASSEMBLY

22

23

24

25

17

26

c.

CLEANING AND INSPECTION

d.

ASSEMBLY

e.

INSTALLATION