TM 9-2330-390-14&P

NOTES:

1. CASTER WHEEL ASSEMBLY. Semiannually,

lubricate fittings on wheel and on fork with WTR. To

gain access, deflate tire or remove wheel.

4. LIFT CYLINDERS. Semiannually, lubricate fit-

ting on each end of lift cylinders with WTR.

2. ENGINE CRANKCASE.

5. FRONT DRAWBAR. Semiannually, lubricate

two fittings with WTR.

a.

Dally, remove dipstick from crankcase and

check level of oil. Level must show on

dipstick. Oil level Is FULL If oil coats threads

of dipstick. Add oil as required (see para-

graph 3-8).

NOTE

If engine Is new, the following service

MUST be performed after initial week of

operation.

b.

Semiannually, remove drain plug and drain

all oil from crankcase. Remove oil filter and

clean. Install filter and drain plug, and fill

crankcase through filler opening until oil

level shows on dipstick (see para-

graph 4-118).

NOTE

If dolly set was required to ford water that

covered the wheel hubs, have Unit Mainte-

nance check, clean, and lubricate wheel

beatings.

6.

HYDRAULIC RESERVOIR. Weekly, before op-

eration, lower dolly set to ground and retract all

hydraulic cylinders. Remove cap and check level of

hydraulic fluid on dipstick. Add hydraulic fluid

(Item 15, Appendix F) as required (see para-

graph 3-7).

7.

FRONT AND REAR PIVOTING TRAY BEAR-

INGS. Semiannually, lubricate fitting at each bearing

with WTR.

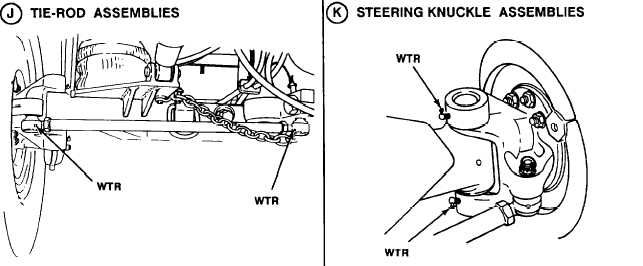

8. TIE-ROD ASSEMBLIES. Semiannually, lubri-

cate fitting on each end of tie-rod assemblies with

WTR.

3. WHEEL BEARINGS. Annually, remove wheel

bearings, clean, inspect, pack with WTR, install, and

adjust (see paragraph 4-75 and TM 9-214).

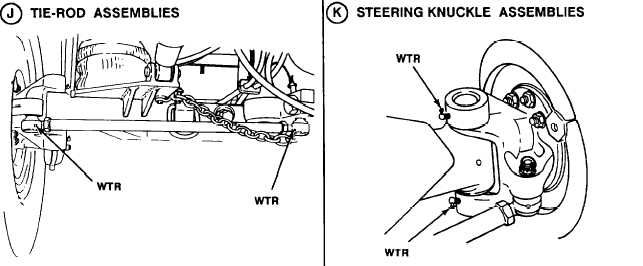

9.

STEERING KNUCKLE ASSEMBLIES. Semian-

nually, lubricate two fittings with WTR.

10. STEERING LINK. Semiannually, lubricate fitting

with WTR.

11. OIL CAN POINTS. Semiannually, lubricate

stowage, top hook, pivoting tray lockout brace, and

telescopic brace pins with PL-S (Item 24, Appen-

dix F).

3-8