TM 10-8340-205-13&P

(c) Small rips and holes, splitting of seams, lines which are beginning to rot, or anything else which does

not appear to be in a normal condition.

4.6 INSTALLATION INSTRUCTIONS .

a. Tools, Test Equipment. and Materials Required for Installation.

Mallet, Wooden (Appendix E)

Repair Kit, Tentage (Appendix E)

b. Assembly of Equipment. Refer to paragraph 2.7.

4.7 PRELIMINARY SERVICING AND ADJUSTMENT OF EQUIPMENT .

Perform the PMCS shown in Table 2-1.

SECTION III. UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICE

(PMCS)

4.8 GENERAL

To ensure that the tent is ready for use at all times, it must be periodically inspected and serviced so that

defects may be discovered and corrected before they result in serious damage or equipment failure. The

PMCS to be perform are listed and described in Table 4-1. The numbers in the Item No. column show the

order in which the check or service should be done. These numbers should be used when recording

deficiencies and shortcomings on DA Form 2404, Equipment Inspection and Maintenance Worksheet.

NOTE

Tents which are in administrative storage should be inspected semiannually;

however, the inspection should be limited to removing the cover to look for

mildew, insects, or rodent damage.

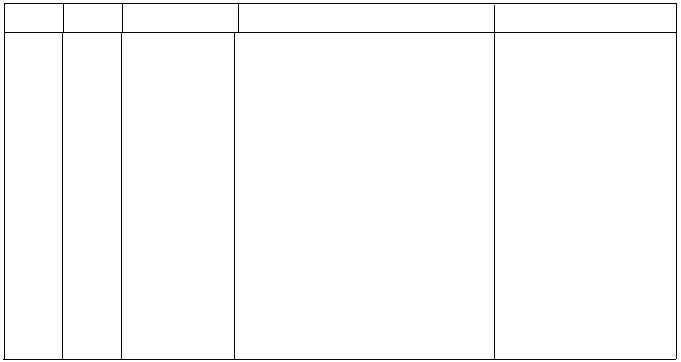

Table 4-1. Unit Preventive Maintenance Checks and Services

Item

Location of Item

Not Fully Mission

No.

Interval

to Check/Service

Procedure

Capable if:

NOTE

If the equipment must be kept in

continuous operation, do only the

procedures that can be done without

disturbing operation Make complete

checks and services when the equip-

ment is shut down.

1

Quarterly Tent Body

a. Fabric

Inspect for abrasions, mildew, holes, poor

Excessive abrasions, exces

condition of previous repairs, broken

sive mildew, large tears or

stitches, evidence of leaks, low tensile

holes Previous repairs are it

strength, and missing or damaged

poor condition. Missing

grommets.

stitches, evidence of leak

age, fabric tears easily an(

grommets are missing or ton

away from material causing

fabric to tear

4-3