TM 10-5411-235-13

DIRECT SUPPORT MAINTENANCE-GENERAL RIVNUT REMOVAL AND INSTALLATION

PROCEDURES

0029 00

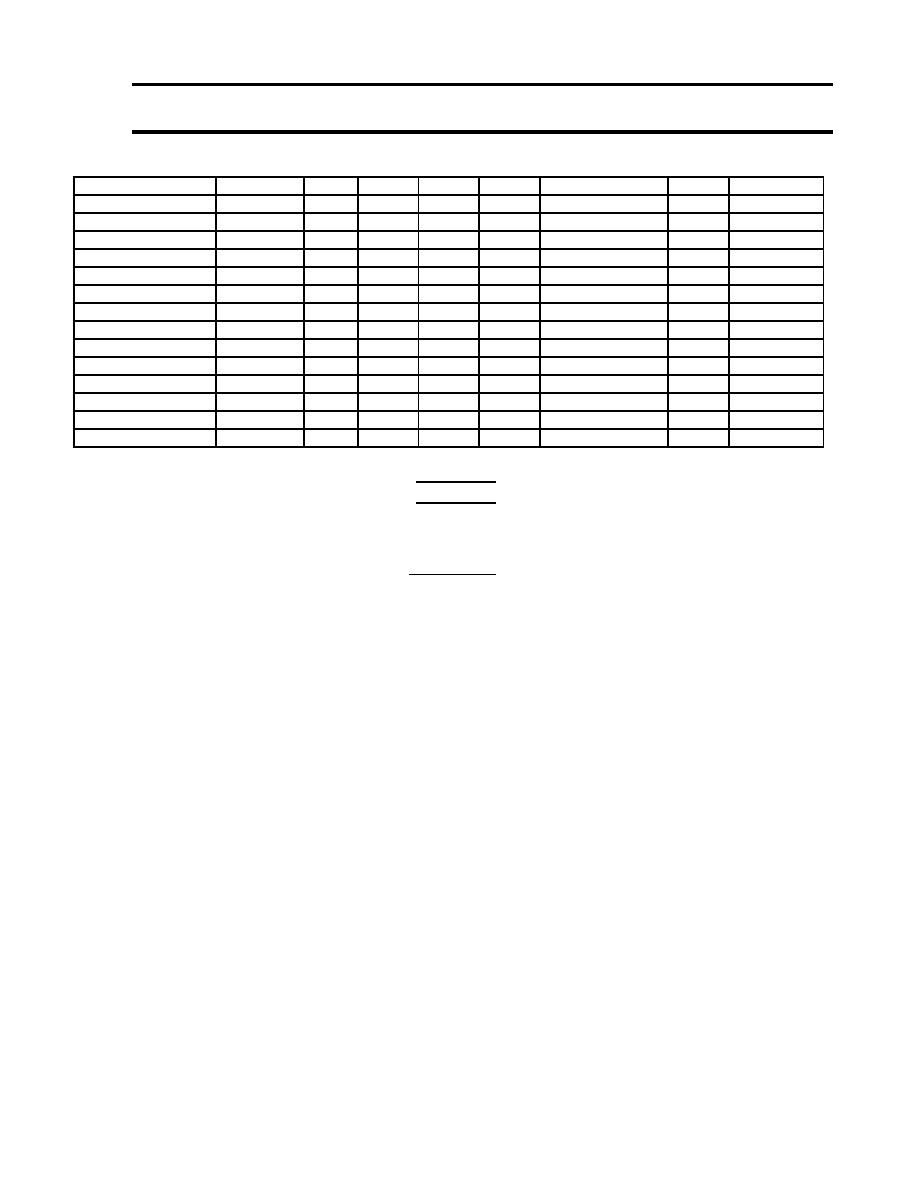

Table 1. Rivnuts

Dash No.

Part no

Style

Dim A Dim D Dim L

T

Dim C

Grip Range

SM-C-563711-1

S25B151

C

0.529

0.332

1.000

-20 UNC-3B

.089-.151

SM-C-563711-2

S25B211

C

0.529

0.332

1.062

-20 UNC-3B

.151-.211

SM-C-563711-3

S25B451

C

0.529

0.332

1.312

-20 UNC-3B

.391-.451

SM-C-563711-4

S10B366

C

0.391

0.250

1.094

10-32 UNC-3B

.316-.366

SM-C-563711-5

S25B140

E

0.475

0.332

1.000

-20 UNC-3B

0.058

.080-.140

SM-C-563711-6

S8B106

C

0.355

0.221

0.687

8-32 UNC-3B

.065-.106

SM-C-563711-7

S31B350

D

0.665

0.413

1.032

5/16-18 UNC-3B

0.062

.275-.350

SM-C-563711-8

S31B125

E

0.665

0.413

1.187

5/16-18 UNC-3B

0.062

.030-.125

SM-C-563711-9

S31B481

C

0.656

0.413

1.562

5/16-18 UNC-3B

.406-.481

SM-C-563711-10

S8B201

C

0.355

0.221

0.687

8-32 UNC-3B

.161-.201

SM-C-563711-11

SS8B161

C

0.355

0.221

0.687

8-32 UNC-3B

.106-.161

SM-C-563711-12

S25B320

E

0.475

0.332

1.187

-20 UNC-3B

0.058

.260-.320

SM-C-563711-13

S31B425

E

0.665

0.413

1.531

5/16-UNC-3B

0.062

.350-.425

SM-C-563711-14

S31B350

E

0.665

0.413

1.437

5/16-18 UNC-3B

0.062

.275-.350

WARNING

Drilling creates metal chips which may enter eyes and

cause serious injury. Eye protection is required.

CAUTION

Make sure drill bit has a stop attached which will prohibit

the drill from exceeding a depth of one inch.

NOTE

Drill hole size must match size of rivnut being installed.

Quantities of sheets may be drilled at the same time when

held together with sheet fasteners.

a. Drill hole in structure.

b. Remove all metal chips and remove burrs from drilled holes.

c.

If a countersunk rivet is being installed, countersink hole using a 100-degree machine

countersink.

d. Thread stem of appropriate pull-up stud into rivnut. Stud should protrude through open end

rivnuts or be 1-1/2 threads from bottoming in closed end rivnuts.

e. Coat rivnut body with fiber filled polyester resin before installing.

f.

Insert rivnut into hole. Make sure sheets are held tightly together before pulling.

g. With pull-up stud parallel to axis of rivnut, pull up on rivnut. Exert firm pressure, but do not

buckle metal sheets.

h. Make sure fastened parts are not loose, rivnut does not rotate, and rivnut head is seated

tightly against surface. Make sure rivnut threads are in good condition. If threads are

damaged or rivnut is improperly installed, remove it and install a new one.

0029 00-3