TM 10-5411-200-14

T.O. 35E4-177-1

4-32.

(cont)

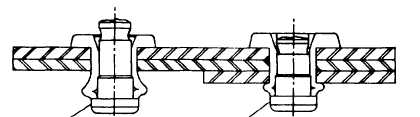

(b) Operation II - Knock out drilled pin and remove upper

portion of pin and lock collar.

(See page 4-187)

(c) Operation III - Counterbore sleeve.

(See page 4-188)

(d) Operation IV - Knock out counterbored sleeve and remove

head of sleeve.

(See page 4-189)

NOTE

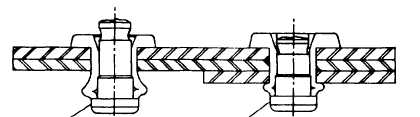

The illustration of the operations for removal show

a countersunk blind bolt.

The removal of a pro-

truding head blind bolt is the same.

A micro-limit

tool is used with the counterbore cutter in Operation

III to control the depth of the cut.

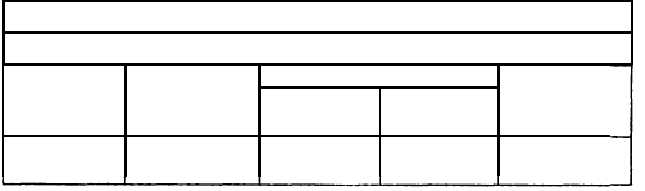

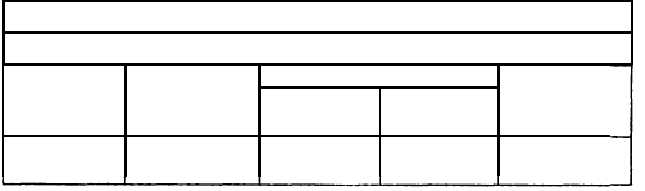

TABLE I

VISUAL INSPECTION TABLE

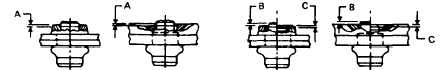

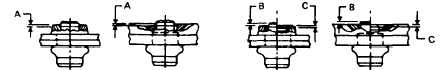

Collar

Lock Position

Minimum

Rivet

Position

“B” max.

“C” max.

Blind Head

Dia.

“A” max.

above

below

Diameter

3/16”

.022”

.012”

.012”

.238”

1/4”

.029”

.015”

.015”

.315”

INSPECTION OF

LOCKING COLLAR

INSPECTION OF

POSITION

PIN POSITION

BOLT TOO LONG

BOLT TOO SHORT

PIN WILL PROTRUDE

PIN WILL EXTEND

TOO FAR

TOO FAR IN HEAD

A

- Maximum allowable distance of locking collar

head.

B

- Maximum allowable distance of top of land on

c

- Maximum allowable distance of top of land on

4-152

above or below fastener

pin above fastener head.

pin below fastener head.